Blog

Marshall Stability Test Equipment: Ensuring Asphalt Quality and Performance

Marshall Stability Test Equipment: Ensuring Asphalt Quality and Performance

Introduction to Marshall Stability Test Equipment

Marshall Stability Test Equipment is a critical component in asphalt testing, used to measure the stability and flow properties of bituminous mixtures. The Marshall stability test is widely applied in road construction and pavement design to ensure that asphalt mixes can withstand traffic loads, temperature fluctuations, and environmental stresses. This test helps engineers determine the optimum binder content, ensuring durability and performance over time.

Accurate Marshall stability testing helps prevent premature pavement failures, such as rutting, cracking, and stripping. By ensuring that asphalt mixtures have the necessary strength and flexibility, the test contributes to longer-lasting roads and highways, reducing the need for costly maintenance and repairs.

Importance of Marshall Stability Testing in Asphalt Pavements

Marshall stability testing plays a key role in asphalt quality control by:

- Ensuring Load-Bearing Capacity: Verifies that asphalt can handle expected traffic loads.

- Optimizing Mix Design: Helps determine the best asphalt-binder ratio.

- Enhancing Pavement Durability: Prevents deformation, rutting, and cracking.

- Meeting Regulatory Standards: Ensures compliance with ASTM D6927, AASHTO T245, and EN 12697-34 guidelines.

- Reducing Maintenance Costs: Ensures long-term road performance, minimizing repairs.

- Improving Sustainability: By optimizing asphalt mix designs, material waste is minimized, leading to environmentally friendly construction practices.

Essential Components of Marshall Stability Test Equipment

A complete Marshall Stability Test Equipment setup typically includes:

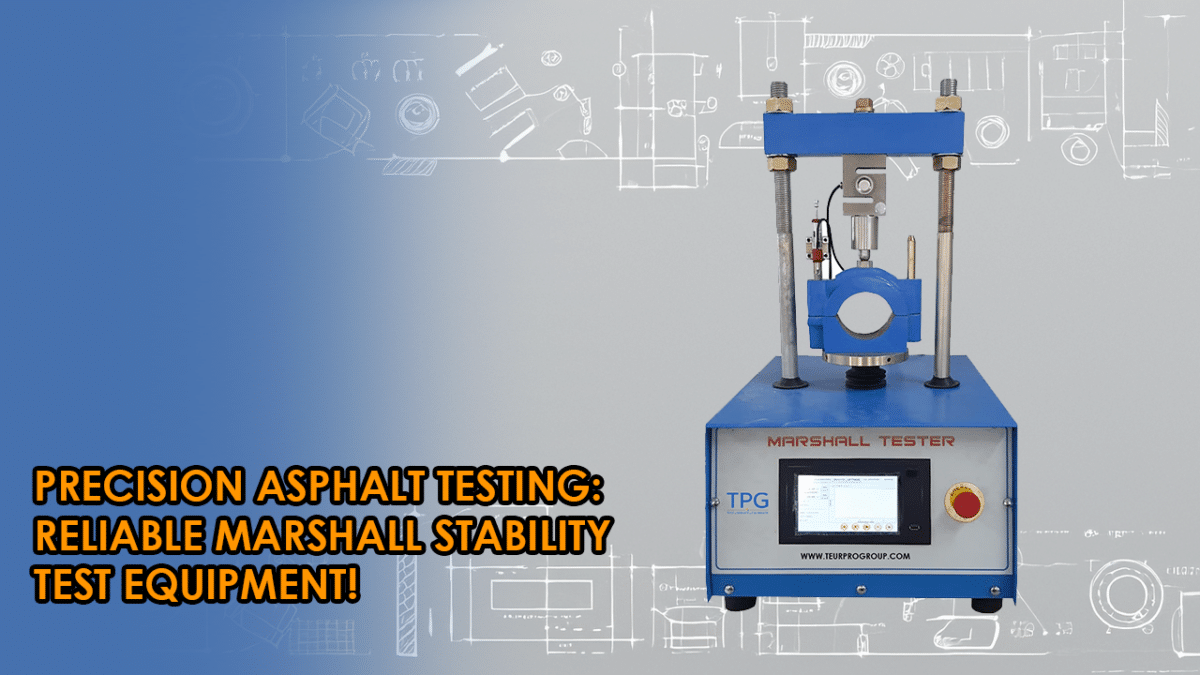

1. Marshall Stability Testing Machine

- Applies controlled compression to asphalt specimens.

- Equipped with a load cell or proving ring to measure stability.

- Features a digital or analog dial gauge to record flow values.

- Available in automatic and manual models for different testing needs.

2. Compaction Molds and Hammer

- Marshall Compaction Molds: Used to prepare cylindrical asphalt samples.

- Automatic or Manual Compactors: Ensure uniform sample density.

- Standardized Hammer Weight and Drop Height: Maintains test consistency.

3. Water Bath for Conditioning

- Temperature-Controlled Bath: Ensures asphalt samples are conditioned before testing.

- Compliance with ASTM and AASHTO standards.

- Precise Temperature Regulation: Prevents inaccuracies in stability results.

4. Specimen Extractor

- Facilitates safe and easy removal of compacted samples from molds.

- Prevents damage to asphalt specimens before testing.

- Available in manual and hydraulic models for different lab setups.

5. Flow Measurement Devices

- Dial gauge or digital systems measure the plastic deformation (flow) of asphalt samples during testing.

- Ensures consistent measurement of asphalt mix flexibility and resistance to deformation.

How the Marshall Stability Test is Performed

The Marshall Stability Test follows a structured testing procedure:

- Sample Preparation: Asphalt mix is compacted into a standard mold using a Marshall hammer.

- Conditioning: The sample is submerged in a water bath at 60°C for 30-40 minutes.

- Load Application: The specimen is placed in the Marshall Stability Testing Machine.

- Measurement: Load is applied until sample failure, recording the peak stability load and flow value.

- Analysis: Results are compared with design specifications to ensure compliance and durability.

- Reporting: Digital testing machines can generate reports for quality assurance and regulatory documentation.

Choosing the Right Marshall Stability Test Equipment

When selecting Marshall Stability Test Equipment, consider:

- Testing Capacity: Ensure the machine meets project requirements.

- Digital vs. Analog Readout: Digital models offer higher precision.

- Automation Features: Automatic compactors improve repeatability and efficiency.

- Standard Compliance: Ensure adherence to ASTM, AASHTO, and EN standards.

- Durability and Maintenance: High-quality materials enhance equipment lifespan.

- Data Logging and Reporting: Advanced models provide automated test data storage.

Why Choose Teur Pro Group for Marshall Stability Test Equipment?

Teur Pro Group provides high-performance Marshall Stability Test Equipment, offering:

- Certified and Compliant Machines: Meeting international asphalt testing standards.

- Advanced Digital Solutions: Ensuring precision and efficiency in asphalt analysis.

- Technical Support and Calibration Services: Keeping your equipment operating optimally.

- Competitive Pricing and Custom Solutions: Tailored to meet various testing needs.

- Long-Term Reliability: Built with high-quality materials for extended durability.

Conclusion

The Marshall Stability Test is a vital process in asphalt mix design, road construction, and pavement quality assurance. Using the right Marshall Stability Test Equipment ensures that asphalt mixtures meet durability, strength, and performance criteria, reducing long-term maintenance costs and ensuring road safety. By investing in high-quality stability testing equipment, engineers and contractors can guarantee consistent, reliable, and regulation-compliant results.

Contact us today to learn more about our equipment and the services we offer! Teur Pro Group Contact

Follow us on LinkedIn for more! Teur Pro Group LinkedIn