Blog

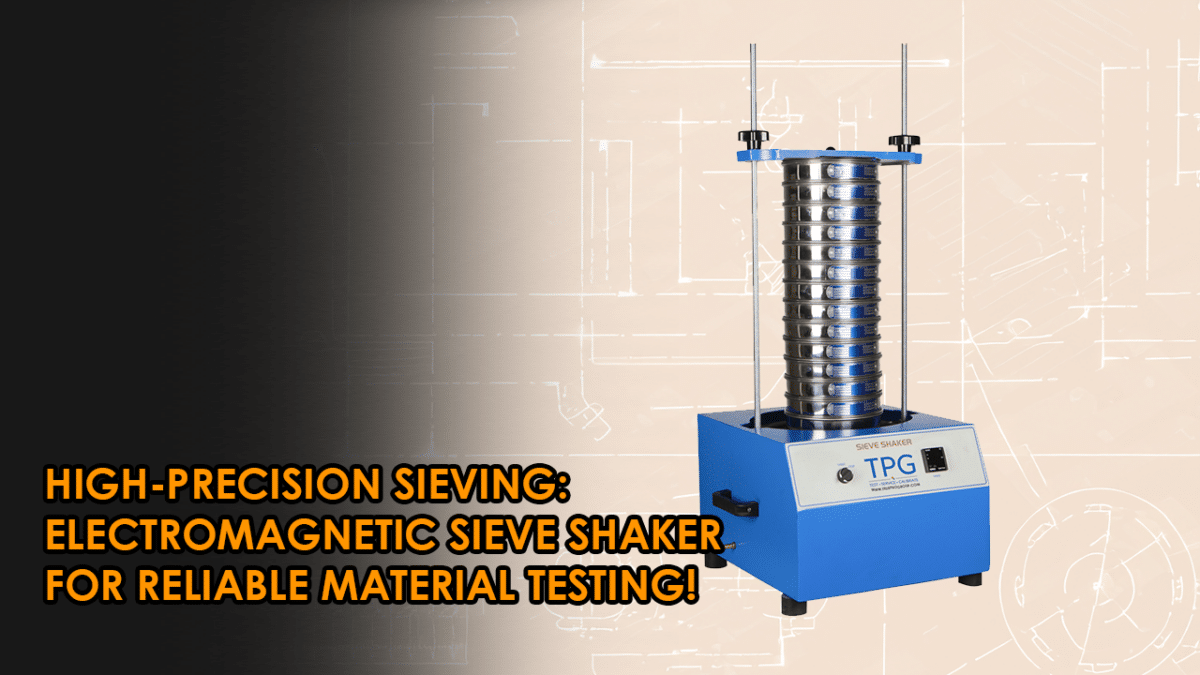

Electromagnetic Sieve Shaker: Precision Particle Size Analysis

Electromagnetic Sieve Shaker: Precision Particle Size Analysis

Introduction to Electromagnetic Sieve Shaker

An Electromagnetic Sieve Shaker is an advanced laboratory device used for precise particle size analysis in various industries, including construction, pharmaceuticals, and material testing. Unlike traditional mechanical sieve shakers, an electromagnetic model provides high-frequency vibrations to ensure uniform and efficient sieving of fine particles.

This equipment is widely used in soil, cement, aggregate, and powder analysis to determine material consistency and quality, making it an essential tool in research and quality control laboratories. Accurate particle size distribution analysis helps industries optimize product performance, durability, and compliance with international standards.

Importance of Sieve Shaking in Material Testing

Sieve analysis is a fundamental process in material testing, ensuring:

- Accurate particle size distribution measurement for quality control.

- Compliance with industry standards, including ASTM E11, ISO 3310, and EN 933-2.

- Efficient separation of granular materials for improved mix designs in construction.

- Repeatable and reliable results due to consistent vibratory action.

- Optimization of material properties, helping industries improve product uniformity and performance.

A well-conducted sieve analysis ensures that materials such as cement, aggregates, and powders meet industry standards, reducing waste and improving efficiency in various applications.

Key Features of an Electromagnetic Sieve Shaker

A high-quality Electromagnetic Sieve Shaker includes:

- Electromagnetic Drive System: Generates uniform, high-frequency vibrations for precise sieving.

- Variable Amplitude and Frequency Control: Allows adjustment for different material types.

- Noise Reduction Technology: Operates more quietly than traditional mechanical shakers.

- Digital Timer and Programmable Settings: Enables precise and automated testing cycles.

- Compatible with Various Sieve Sizes: Works with standard test sieves for different applications.

- Compact and Durable Design: Ideal for laboratory environments with space constraints.

- Improved Sample Processing Time: Allows faster sieving with greater accuracy, increasing productivity in quality control labs.

How an Electromagnetic Sieve Shaker Works

The Electromagnetic Sieve Shaker operates through the following steps:

- Sieve Stack Preparation: Standardized sieves are arranged based on required particle size distribution.

- Sample Loading: The material is placed into the top sieve.

- Vibration Mechanism Activation: Electromagnetic pulses generate consistent vertical movement.

- Material Separation: Particles pass through different sieve mesh sizes based on their dimensions.

- Result Collection and Analysis: The retained material in each sieve is weighed and recorded.

- Data Reporting: Digital models allow test results to be stored and exported for further analysis.

The device ensures rapid and efficient material separation, reducing testing time while improving precision. Unlike conventional sieve shakers, electromagnetic models provide more uniform motion, preventing sample clogging and improving reproducibility.

Applications of Electromagnetic Sieve Shakers

- Construction Industry: Used for grading sand, cement, and aggregate materials.

- Pharmaceuticals: Ensures precise powder granulation for medication production.

- Food Industry: Analyzes flour, sugar, and other fine powders for quality assurance.

- Mining and Geology: Determines the composition of soil and mineral samples.

- Chemical Processing: Helps in refining powders and granular substances for industrial use.

- Environmental Testing: Used for analyzing soil and sediment samples in environmental studies.

Choosing the Right Electromagnetic Sieve Shaker

When selecting an Electromagnetic Sieve Shaker, consider:

- Amplitude and Frequency Adjustability: Ensures compatibility with different material types.

- Digital vs. Manual Controls: Digital models offer automated settings for enhanced precision.

- Capacity and Sieve Compatibility: Supports multiple sieve sizes for versatile applications.

- Durability and Maintenance Needs: Choose models with robust construction and easy maintenance.

- Standard Compliance: Ensure the device meets ASTM, ISO, and EN specifications.

- Data Logging Capabilities: Advanced models allow automated data collection for reporting and quality control.

Why Choose Teur Pro Group for Electromagnetic Sieve Shakers?

Teur Pro Group provides state-of-the-art Electromagnetic Sieve Shakers, offering:

- Certified and Compliant Equipment: Meeting international material testing standards.

- Advanced Digital Features: Ensuring accurate and repeatable test results.

- Technical Support and Calibration Services: Maximizing long-term equipment performance.

- Competitive Pricing and Custom Solutions: Tailored to different testing needs.

- Reliable Build Quality: Designed for long-term laboratory and industrial use.

- Expert Consultation: Our team helps you select the right equipment for your specific applications.

Conclusion

The Electromagnetic Sieve Shaker is an essential tool for accurate particle size analysis in construction, pharmaceuticals, mining, and research laboratories. Its high-frequency electromagnetic vibration system ensures precise, repeatable, and efficient sieving, improving material quality and compliance with industry standards. Investing in a high-quality electromagnetic sieve shaker enhances laboratory efficiency, speeds up testing processes, and guarantees reliable material assessments.

Contact us today to learn more about our equipment and the services we offer! Teur Pro Group Contact

Follow us on LinkedIn for more! Teur Pro Group LinkedIn