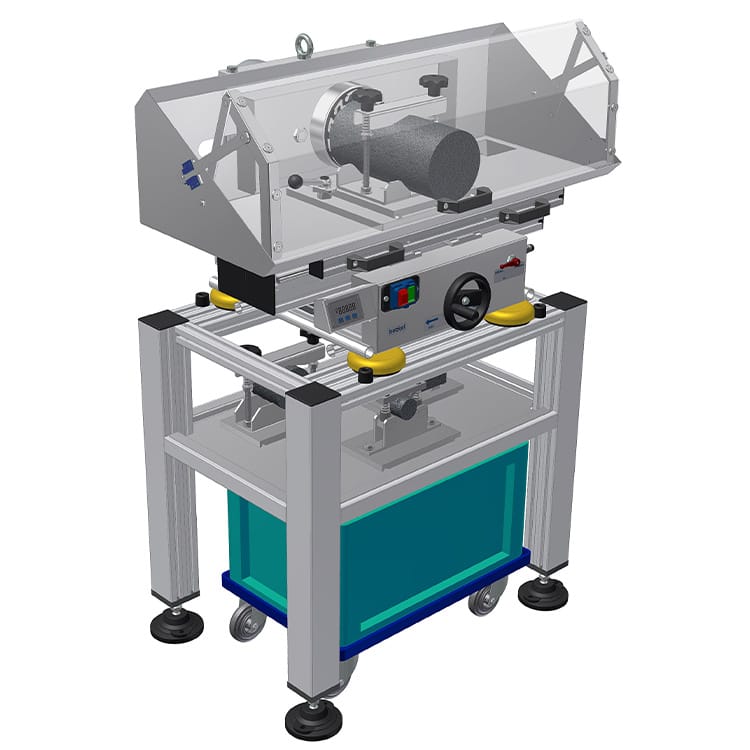

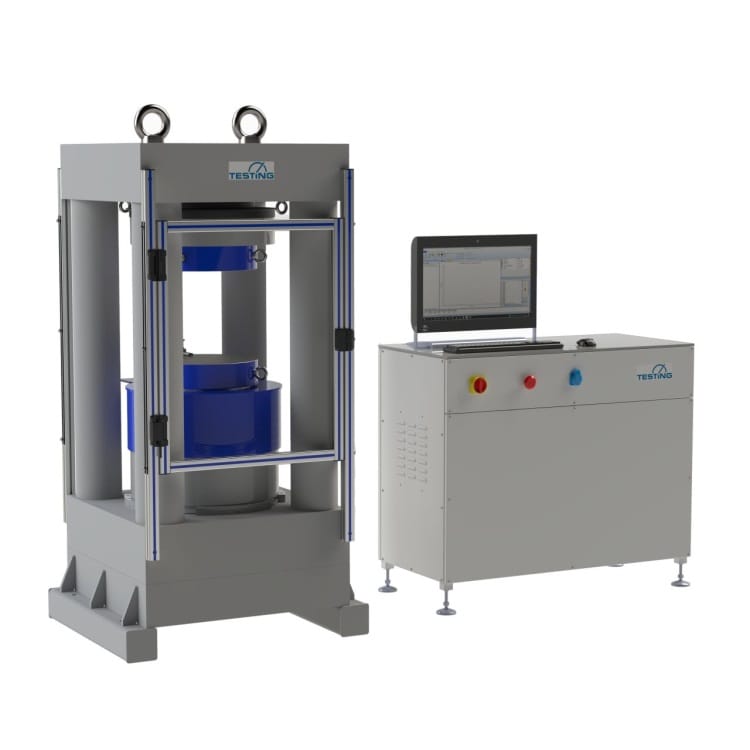

The Automatic Grinding Machine is designed to prepare precise and parallel specimen surfaces for rock and concrete samples. With a robust frame, safety cabinet, and automatic operation, it ensures fast, consistent, and repeatable sample preparation for further testing.

Equipped with a rotating table and diamond grinding head, the machine provides high surface quality and dimensional accuracy. Making it ideal for laboratories conducting uniaxial compressive strength, triaxial, or point load tests.

Depending on the model, features may include touchscreen control, programmable grinding cycles, integrated dust extraction, and protective soundproof cabinets to enhance safety and ease of use.

Whether in research or routine testing, this machine ensures your samples are always test-ready.

Here’s a quick brand-to-brand comparison of available automatic grinding machines, helping you select the model that fits your testing workflow best.

Features |  |  |  |

|---|---|---|---|

| Sample Types | Rock & Concrete specimens | Rock & Concrete specimens | Concrete cylinders, cubes, cores |

| Grinding Disc | Diamond disc | Diamond disc | Diamond grinding wheel |

| Operation | Fully automatic | Automatic | Automatic |

| Table Type | Rotating circular table | Circular rotating table | Slidable platform |

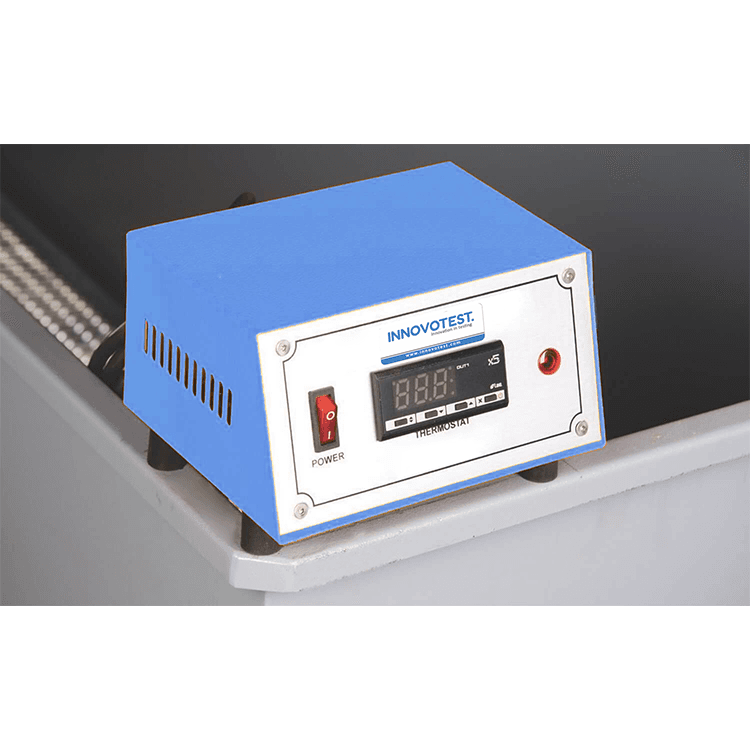

| Control System | Digital touchscreen | Touch panel + programmable settings | Manual panel with preset time |

| Safety Cabinet | Included (with soundproofing) | Integrated cabinet with transparent door | Protective cover (optional) |

| Dust/Splash Protection | Yes – Enclosed cabinet | Yes | Yes |

| Specimen Size Range | Up to 150 mm diameter | Up to 160 mm diameter | Up to 160 mm diameter |

| Power Supply | 230 V / 50–60 Hz | 220 V / 50 Hz | 400 V / 50 Hz |

| Extras / Accessories | Clamping fixtures, safety kit | Sample holder set | Clamping device (optional) |