Blog

Air Entrainment Meter: Essential Equipment for Concrete Durability

Air Entrainment Meter: Essential Equipment for Concrete Durability

Introduction to Air Entrainment Meter

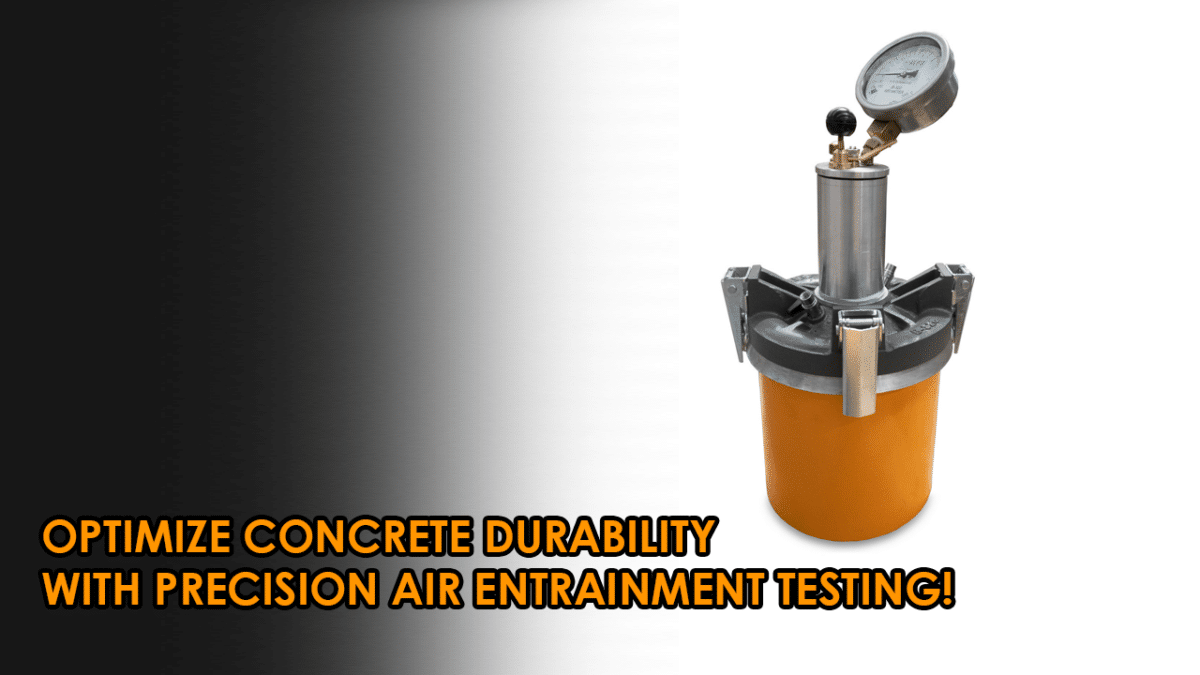

An Air Entrainment Meter is a crucial device used in concrete testing to measure the air content within fresh concrete mixes. Air entrainment is essential for improving the durability and freeze-thaw resistance of concrete, particularly in regions exposed to extreme weather conditions. The meter ensures that the concrete mix contains the optimal amount of entrained air, preventing structural weaknesses and enhancing long-term performance.

Proper air entrainment in concrete can significantly impact the lifespan and structural integrity of buildings, bridges, and roads. Without adequate air content, concrete can suffer from cracking, spalling, and overall deterioration, especially when exposed to cycles of freezing and thawing. Therefore, using an Air Entrainment Meter is crucial for quality control and compliance in modern construction projects.

Importance of Air Entrainment in Concrete

Air entrainment refers to the intentional introduction of tiny air bubbles into the concrete mix using chemical admixtures. These air voids enhance concrete properties by:

- Increasing Freeze-Thaw Resistance: Protects against cracking in cold climates.

- Improving Workability: Enhances the ease of placement and finishing.

- Reducing Permeability: Prevents water absorption and enhances durability.

- Enhancing Resistance to Deicing Chemicals: Mitigates surface scaling and deterioration.

- Improving Pumpability: Air entrainment makes concrete easier to transport and pour, reducing segregation.

How an Air Entrainment Meter Works

The Air Entrainment Meter operates based on Boyle’s Law, which relates the volume of entrained air to pressure changes. The standard procedure involves:

- Filling the Chamber: Fresh concrete is placed into the test chamber.

- Applying Pressure: A predetermined pressure is applied to the sample.

- Measuring Air Content: The decrease in volume is recorded, which corresponds to the air content percentage.

- Recording and Adjustments: If necessary, adjustments to the concrete mix are made based on the test results.

- Calibration Checks: Routine calibration ensures accuracy and compliance with industry standards.

This test follows standards such as ASTM C231 and BS EN 12350-7 to ensure accuracy and consistency. Regular use of an Air Entrainment Meter helps maintain uniformity in concrete quality, reducing material waste and ensuring cost-effective construction.

Key Features of an Air Entrainment Meter

A high-quality Air Entrainment Meter includes:

- Durable Construction: Made from corrosion-resistant aluminum or stainless steel.

- Precision Pressure Gauge: Ensures accurate readings.

- Easy-to-Use Pump Mechanism: Allows precise pressure control.

- Standardized Calibration Features: Ensures compliance with international testing standards.

- Portable Design: Enables field and laboratory testing with ease.

- High-Visibility Readout: Provides clear and precise measurements.

- Sealed Lid and Air-Tight Chamber: Prevents leaks for consistent results.

Applications of Air Entrainment Meters

- Concrete Production: Ensures proper air content before pouring.

- Quality Control in Construction: Verifies compliance with mix design specifications.

- Research and Development: Helps in testing and formulating improved concrete mixtures.

- Infrastructure Projects: Used in highway, bridge, and dam construction to improve concrete durability.

- Precast Concrete Manufacturing: Ensures consistent air content for uniform performance across precast elements.

Choosing the Right Air Entrainment Meter

When selecting an Air Entrainment Meter, consider:

- Compliance with Standards: Ensure it meets ASTM, AASHTO, or EN specifications.

- Ease of Use: Choose a model with clear markings and user-friendly controls.

- Durability: Opt for rugged designs suitable for field and lab conditions.

- Calibration Accuracy: Look for meters with precise pressure adjustments and calibration capabilities.

- Capacity: Ensure the meter can handle the volume of concrete needed for testing.

- Maintenance Requirements: Select models that are easy to clean and maintain for long-term accuracy.

Why Choose Teur Pro Group for Air Entrainment Meters?

Teur Pro Group offers high-quality Air Entrainment Meters designed for reliability and precision. Our advantages include:

- Certified and Compliant Equipment: Meeting global testing standards.

- User-Friendly Designs: Ensuring ease of operation in both laboratory and field settings.

- Technical Support and Calibration Services: Assisting with setup, maintenance, and compliance.

- Competitive Pricing: High-performance equipment at cost-effective rates.

- Long-Term Reliability: Durable materials and robust construction for extended use.

Conclusion

The Air Entrainment Meter is a vital tool for ensuring concrete durability, strength, and freeze-thaw resistance. By accurately measuring entrained air content, it helps engineers and contractors optimize concrete mix designs and meet quality standards. Investing in the right air entrainment testing equipment ensures compliance with industry regulations and enhances the longevity of concrete structures.

Contact us today to learn more about our equipment and the services we offer! Teur Pro Group Contact

Follow us on LinkedIn for more! Teur Pro Group LinkedIn