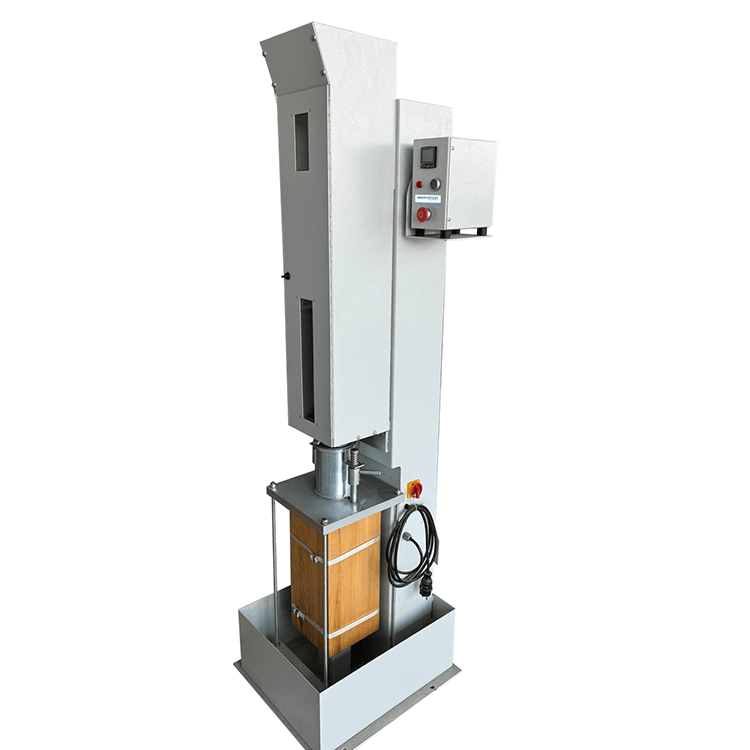

Automatic Marshall Compactor

The Automatic Marshall Compactor is used to produce compacted bituminous specimens for Marshall Stability testing, in accordance with standards such as EN 12697-30, ASTM D6926, and AASHTO T245.

This machine ensures consistent and repeatable compaction of asphalt mixtures with pre-set impact energy, achieved through a falling rammer in a rigid guide structure.

Key features may include:

Adjustable number of blows per side

Compaction mold with base plate and holder

Safety door and automatic stop

Optional soundproof cabinet for noise reduction

The machine is ideal for labs performing high-volume asphalt mix testing or requiring precision and standard compliance in compaction procedures.

Below is a comparison of Marshall Compactors from top brands, designed to streamline your asphalt testing workflow while meeting industry standards.

Key Features Comparison – Automatic Marshall Compactor

| Feature |  |  |  |

|---|---|---|---|

| Standards Compliance | EN 12697-30, ASTM D6926, AASHTO T245 | EN 12697-30, ASTM D6926, AASHTO T245 | ASTM D6926, EN 12697-30 |

| Ram Weight | 4.555 ± 0.020 kg | 4.535 ± 0.015 kg | 4.535 ± 0.015 kg |

| Drop Height | 460 ± 3 mm | 457 mm ± 5 mm | 457 mm ± 5 mm |

| Blows per Side | Adjustable (up to 99) | Adjustable (preset & programmable) | Adjustable (preset on control unit) |

| Compaction Mold Size | Ø 101.6 mm (Standard Marshall mold) | Ø 101.6 mm | Ø 101.6 mm |

| Control System | Digital counter + side control panel | Integrated control panel | Digital counter unit |

| Soundproof Cabinet | Optional | Optional | Optional |

| Safety Features | Automatic stop after set blows, protective door | Automatic stop, safety interlock | Safety limit switch, top cover |

| Construction | Rigid steel frame + vibration damping base | Rigid frame with high impact resistance | Solid cast-iron body + anti-slip base |

| Power Supply | 220 V / 50–60 Hz | 230 V / 50–60 Hz | 230 V / 50–60 Hz |