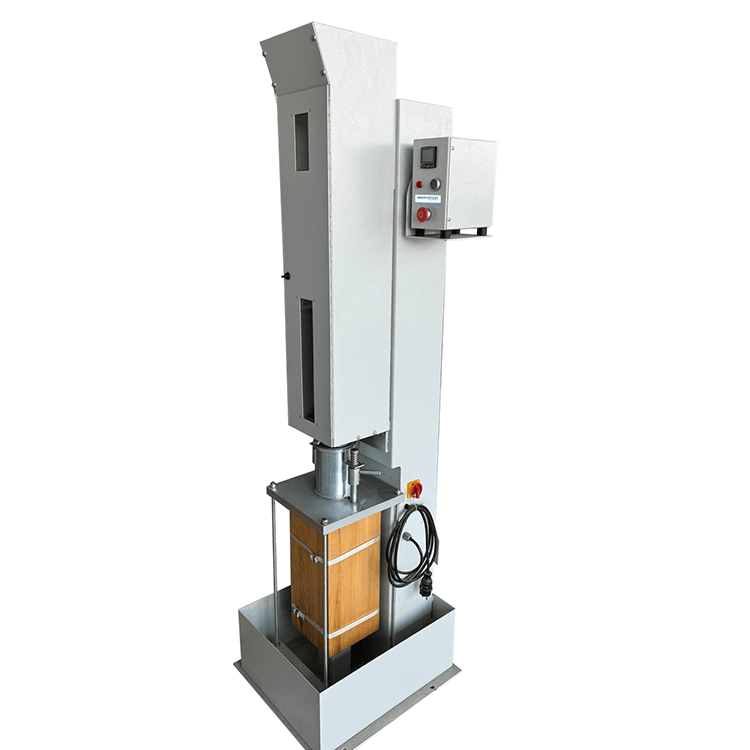

Marshall Stability Test Machine

The Marshall Stability Test Machine is used to determine the maximum load and flow values of bituminous mixtures. This test evaluates the strength and plasticity of asphalt, essential for quality control and performance prediction in road construction.

These machines are designed to apply a constant rate of loading (typically 50.8 mm/min) to Marshall specimens, measuring both the peak load (stability) and the deformation (flow) at failure.

Standard features include:

Load frame with precision movement

Load cell or proving ring for accurate force measurement

Flow measurement via displacement transducer or dial gauge

Control units with digital readout or touchscreen interface

Conforms to ASTM D6927, AASHTO T245, EN 12697-34, and similar international standards.

Here’s a side-by-side look at Marshall Stability testers. Both designed to deliver consistent performance for bitumen testing labs.

Key Features Comparison – Marshall Stability Test Machine

| Feature |  |  |

|---|---|---|

| Standards Compliance | ASTM D6927, EN 12697-34, AASHTO T245 | DIN 1996-4, EN 12697-30 |

| Max Load Capacity | 50 kN | 50 kN |

| Loading Speed | 50.8 mm/min (fixed) | 50.8 mm/min |

| Load Measurement | Precision load cell | Load cell with digital readout |

| Flow Measurement | 25 mm displacement transducer | 25 mm digital displacement sensor |

| Control Interface | 7” TFT touchscreen | Digital control unit |

| Frame Structure | Dual-column steel frame | Dual-column load frame |

| Safety Features | Emergency stop, overload protection | Overload switch, emergency button |

| Included Accessories | Breaking head for Ø100 mm, 25 mm flow sensor | Breaking head Ø100 mm, flow sensor |

| Optional Add-ons | Ø150 mm breaking head, indirect tensile device | Ø150 mm head, ITS fixture available |

| Power Supply | 220-240 V / 50–60 Hz | 400 V / 50 Hz |