Blog

Concrete Cube Testing Equipment: Ensuring Strength and Quality

Concrete Cube Testing Equipment: Ensuring Strength and Quality

What is Concrete Cube Testing?

Concrete cube testing is a fundamental procedure in construction quality control, used to determine the compressive strength of concrete. This process ensures that concrete structures meet design specifications and industry standards, preventing failures and enhancing safety. Testing is conducted using specialized concrete cube testing equipment to apply controlled pressure until the sample breaks, measuring its load-bearing capacity.

Concrete cube testing is performed at different curing intervals, typically at 7, 14, and 28 days, to evaluate how the concrete gains strength over time. By analyzing these results, engineers and construction professionals can make informed decisions about material selection and structural safety.

Essential Concrete Cube Testing Equipment

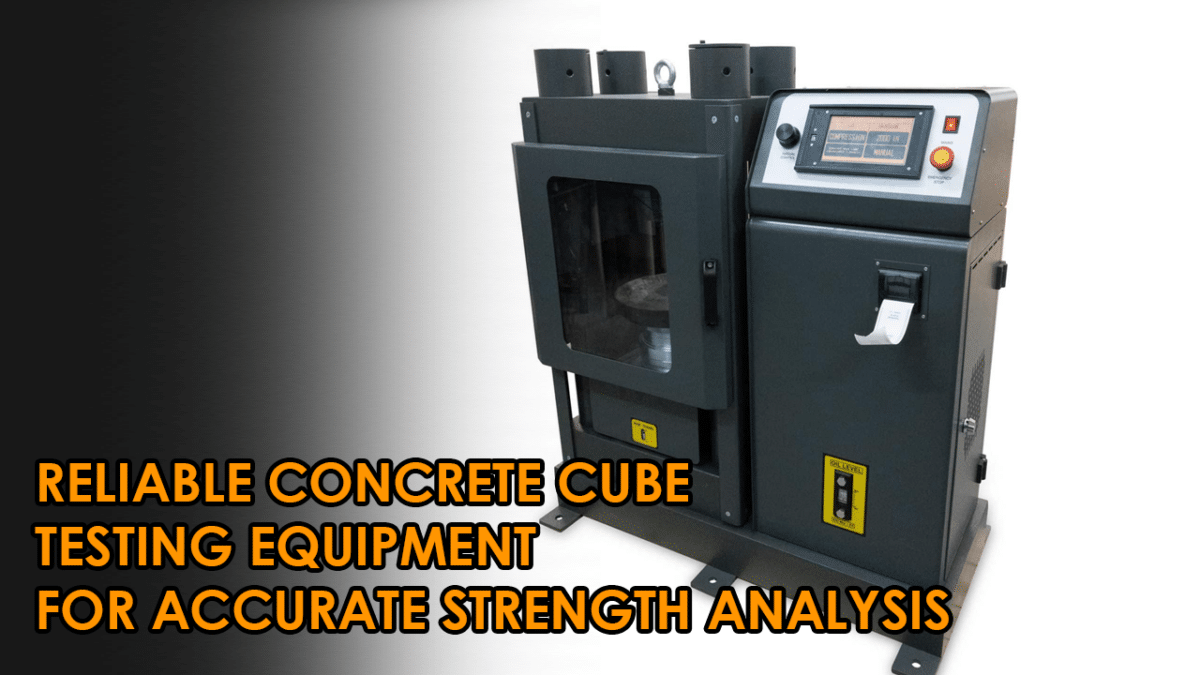

Compression Testing Machine

The compression testing machine is the most critical equipment for concrete cube testing. It applies a gradual load to the concrete cube until failure occurs, providing an accurate measurement of its compressive strength. Key features include:

- High-capacity loading frames to accommodate various cube sizes.

- Digital or analog load indicators for precise readings.

- Compliance with ASTM C39, BS EN 12390, and other industry standards.

- Fully automated models for enhanced accuracy and repeatability.

Concrete Molds and Sample Preparation Tools

Before testing, concrete samples must be prepared using standard molds. These molds ensure uniform cube shapes and proper curing conditions. Essential tools include:

- Steel or plastic cube molds (150mm x 150mm x 150mm or 100mm x 100mm x 100mm).

- Tamping rods and vibrating tables to remove air voids and achieve proper compaction.

- Concrete mixers to ensure homogeneity in sample preparation.

Curing Tanks

Proper curing significantly affects concrete strength. Curing tanks maintain controlled temperature and moisture conditions, ensuring consistent hydration and optimal test results. These tanks come with temperature regulation systems to simulate field conditions.

Digital Calipers and Measurement Devices

Accurate sample dimensions are crucial for correct strength calculations. Digital calipers and other measuring tools help verify cube dimensions before testing. Even small dimensional variations can impact test accuracy, making precise measurements essential.

Factors to Consider When Choosing Concrete Cube Testing Equipment

When selecting concrete cube testing equipment, consider the following:

- Capacity and Accuracy: Ensure the compression machine can handle required loads with high precision.

- Compliance with Standards: Choose equipment that meets ASTM, ISO, or BS specifications.

- Ease of Operation: Look for user-friendly digital displays and automated testing options.

- Durability and Maintenance: Invest in robust equipment that requires minimal maintenance for long-term reliability.

- Data Recording Capabilities: Advanced systems provide digital records for better tracking and reporting.

Applications of Concrete Cube Testing Equipment

Concrete cube testing plays a vital role in various sectors:

- Construction Industry: Verifies concrete mix design and strength compliance.

- Infrastructure Projects: Ensures roads, bridges, and buildings meet regulatory safety standards.

- Research and Development: Assesses new concrete formulations and additives.

- Quality Control Laboratories: Standardized testing for certification and compliance purposes.

- Academic Institutions: Used in engineering research to analyze material properties.

Why Choose Teur Pro Group for Concrete Cube Testing Equipment?

Teur Pro Group provides high-quality concrete cube testing equipment designed for precision and durability. Our products offer:

- Reliable Performance: Advanced technology ensuring consistent and repeatable test results.

- Industry Compliance: Fully certified to meet global construction testing standards.

- Comprehensive Support: Expert calibration, maintenance, and training services.

- Custom Solutions: Equipment tailored to specific industry and project requirements.

- Innovative Features: Cutting-edge automation for precise and efficient testing.

Conclusion

Concrete cube testing is essential for evaluating the strength and quality of concrete structures. Using the right concrete cube testing equipment ensures compliance with industry standards and enhances construction reliability. With advancements in automation and digital analysis, testing processes have become more efficient and accurate. Teur Pro Group offers state-of-the-art testing solutions to meet your needs.

Contact us today to learn more about our equipments and our services we offer! https://teurprogroup.com/contact/

Follow us on linkedin for more!