Curing Tank

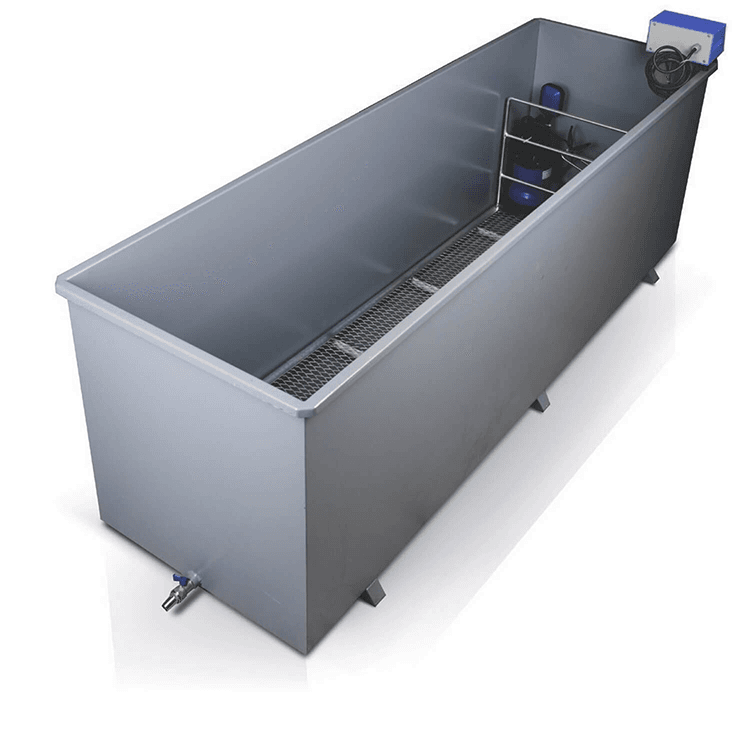

The Curing Tank is essential for the proper hydration and strength development of concrete specimens by providing a controlled temperature water environment during the curing process.

Designed to comply with standards such as EN 12390-2 and ASTM C511, curing tanks ensure that test samples (such as cubes, cylinders, and beams) remain fully submerged at consistent temperature and humidity levels for accurate strength measurement.

Depending on the model and brand, features may include:

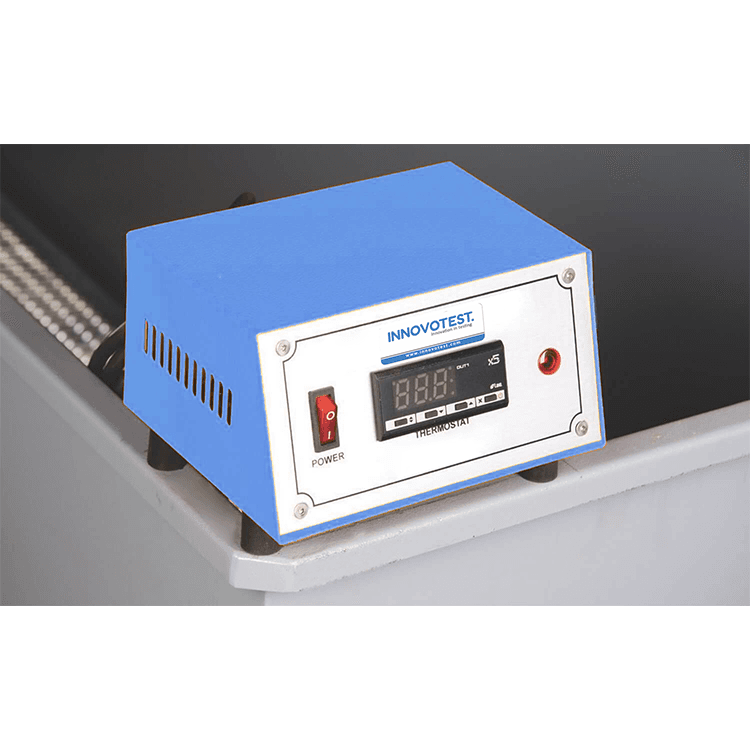

Digital temperature control

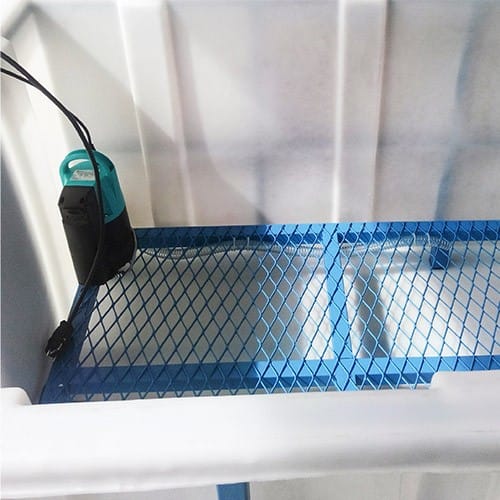

Integrated circulation and heating system

Adjustable temperature settings (typically between +5°C and +50°C)

Optional cooling unit

Insulated body and lid for energy efficiency

Curing tanks are available in various volumes and capacities to accommodate small-scale lab use or high-volume testing operations.

Need to compare curing tanks? Here’s a side-by-side breakdown of features to help you pick the right fit for your concrete testing setup.

| Feature |  |  |  |

|---|---|---|---|

| Available Volumes | 100 / 250 / 500 L | 100 / 250 / 500 L | 250 L |

| Temperature Range | Ambient to +21°C | Ambient to +40°C | -35°C to +105°C |

| Temperature Control | Digital thermostat (PID) | Digital temperature controller | Thermostat control (digital) |

| Circulation System | Integrated water circulation | Yes – Pump circulation system | Yes – Built-in circulation |

| Cooling Option | Optional | Optional | Optional |

| Lid Type | Insulated hinged lid | Hinged plastic lid | Hinged plastic cover |

| Tank Material | Insulated steel or HDPE (model-dependent) | HDPE | HDPE |

| Specimen Types | Concrete cubes, cylinders, prisms | Concrete cubes, cylinders | Concrete cubes, cylinders |

| Standard Compliance | EN 12390-2, ASTM C511 | EN 12390-2, ASTM C511 | EN 12390-2 |

| Accessories Included | Heating element, circulation system, lid | Lid, circulation system | Heating unit, circulation pump |